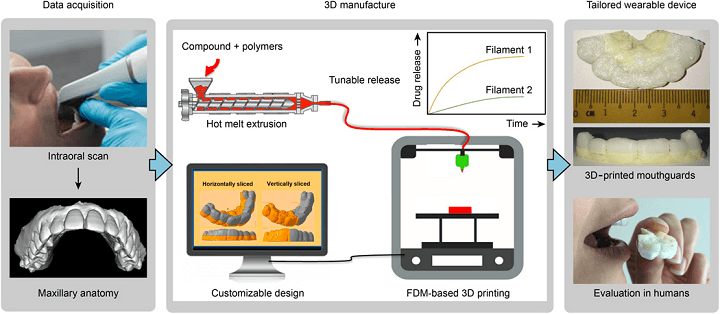

Researchers at ETH Zürich recently published a proof of concept paper regarding oral drug delivery using 3D printed mouthguards.

According to the paper, “A primary reason for the gap between prototyping and application is that, although ample progress has been made in 3D printing technologies, the materials and standardized procedures remain generally inadequate from a pharmaceutical perspective, hampering the development of consistent, scalable, 3D-printed drug-eluting devices.”

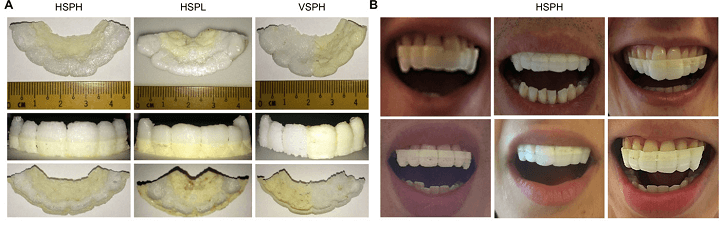

(A) 3D printed VA-loaded mouthguards with three different designs: HSPH, VSPH, and HSPL

(B) Representative images of the 3D printed VA-loaded mouthguards tailored to each volunteer’s maxillary anatomy in the HSPH group.

The paper titled, “3D printing of a wearable personalized oral delivery device: A first-in-human study,” was published in the journal Science Advances.

http://advances.sciencemag.org/content/advances/4/5/eaat2544.full.pdf

The abstract reads, “Despite the burgeoning interest in three-dimensional (3D) printing for the manufacture of customizable oral dosage formulations, a U.S. Food and Drug Administration–approved tablet notwithstanding, the full potential of 3D printing in pharmaceutical sciences has not been realized. In particular, 3D-printed drug-eluting devices offer the possibility for personalization in terms of shape, size, and architecture, but their clinical applications have remained relatively unexplored. We used 3D printing to manufacture a tailored oral drug delivery device with customizable design and tunable release rates in the form of a mouthguard and, subsequently, evaluated the performance of this system in the native setting in a first-in-human study. Our proof-of-concept work demonstrates the immense potential of 3D printing as a platform for the development and translation of next-generation drug delivery devices for personalized therapy.”